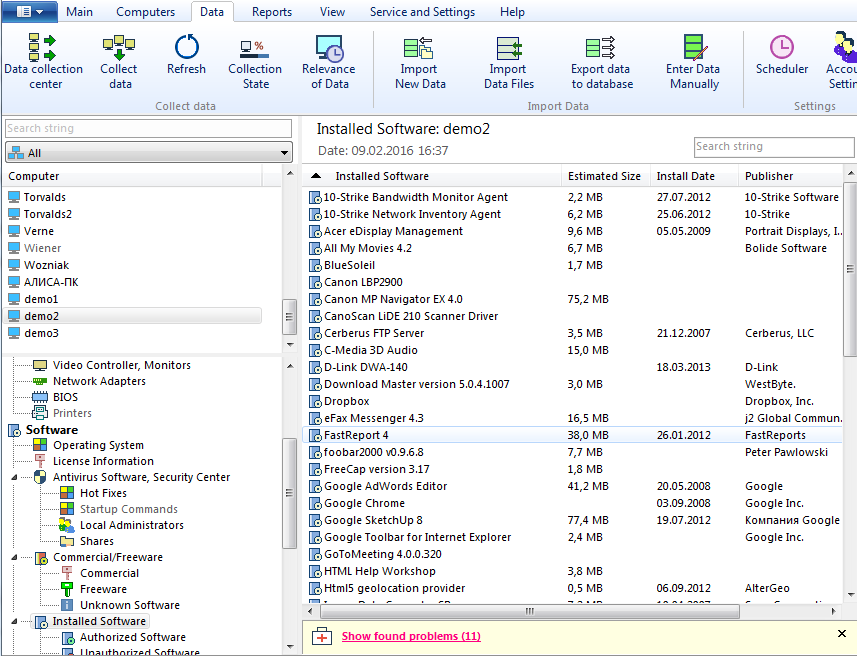

More than 90 percent of buyers typically fall into one of these three categories:įull-suite buyers. Inventory management systems can also track purchase orders and other value information that is helpful for accounting.īefore deciding on which system best fits your needs, it’s important to determine what type of buyer you are. Many systems have barcode, or radio frequency identification (RFID), functionality to scan items that are received, picked or transferred. Inventory management solutions use these numbers to track and locate in-stock items and produce picking information for item retrieval.

INVENTORY SOFTWARE SERIAL

Most inventory systems will track purchased material and stocked items by lot number and/or serial number. In addition to tracking raw materials and stocked items, the system also records work-in-progress (WIP) items, finished products and more. The systems allow manufacturers to instantly determine on-hand inventory balances, which is useful for financial planning. Inventory management software helps optimize supply levels so manufacturers always have what they need as orders are placed, without tying up capital in excess parts or ingredients.

What Is Manufacturing Inventory Management Software? This buyer’s guide, along with our manufacturing inventory software reviews, cover the essential information needed to make a purchase.

For this reason, there are more than 100 vendors that offer some form of manufacturing inventory management software. Manufacturing inventory software, sometimes referred to as manufacturing inventory control software, is one of the more traditional manufacturing applications. Maintaining tight control over inventory is crucial for manufacturers operating in modern manufacturing environments where stock is kept at a minimum and orders are filled just in time (JIT).

0 kommentar(er)

0 kommentar(er)